Volvo excavators are equipped with powerful engines that are essential for their performance and productivity. To ensure that the engine operates smoothly and efficiently, it is important to understand the engine body instructions, perform basic inspections, and troubleshoot any potential issues. In this article, we will delve into these topics to help you maintain and optimize your Volvo excavator’s engine.

Engine Description

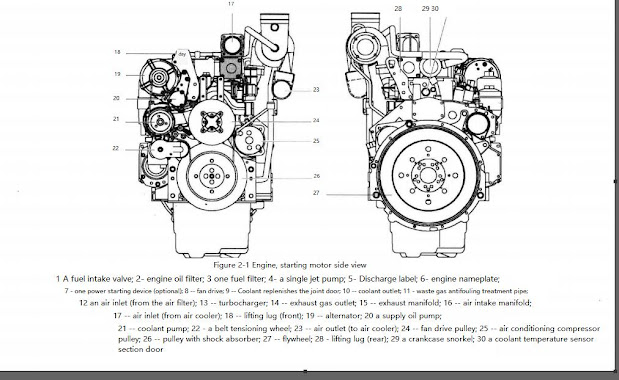

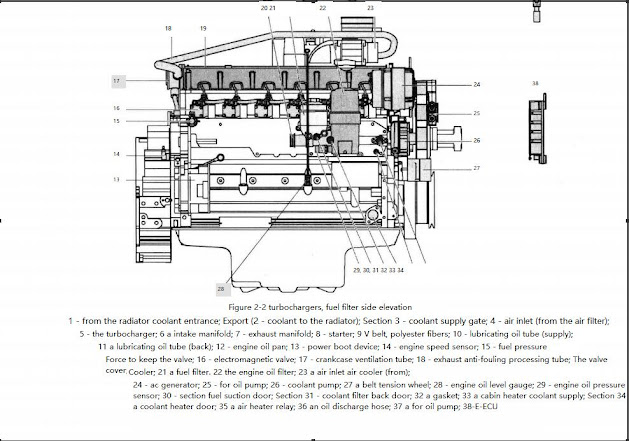

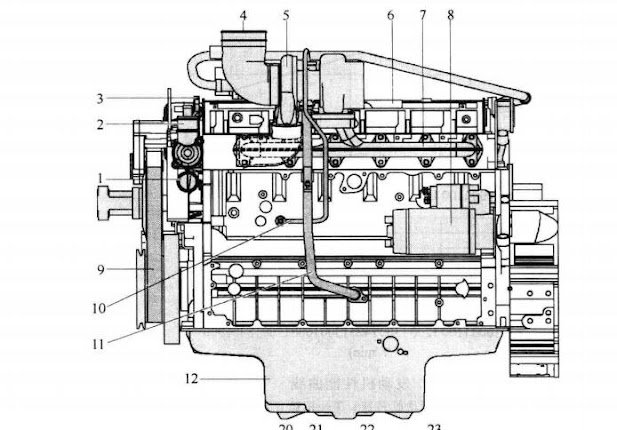

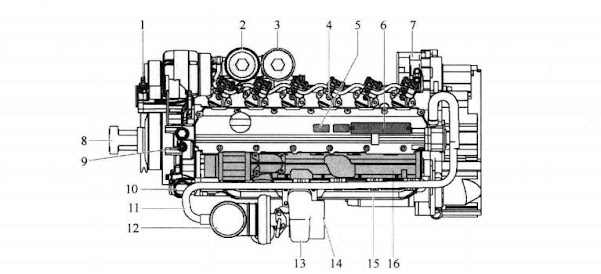

The Volvo excavator engine is a 6-cylinder, 4-stroke, direct injection, turbocharged, and aftercooled engine. It features a cast iron block and cylinder head, which provide durability and robustness. The engine is designed with internal passages for lubricating oil and coolant, ensuring efficient cooling and lubrication. The gears in the engine gearbox are hardened helical type, offering both strength and noise reduction for quiet and smooth power transmission. The fan belt is a polyester V-belt, designed to enhance performance and is held in place by an automatic tensioner.

Instructions for Troubleshooting

When encountering a malfunction in your Volvo excavator engine, it is crucial to identify the cause promptly. The starting point for troubleshooting is recognizing the symptoms or malfunctions. Faults can be indicated by the generation of error codes or the detection of malfunctions.

1. Troubleshooting Operation

The initial step in troubleshooting is to gather information about the fault performance from the operator. Then, proceed to determine the cause by following a specific order of checks. The different inspection steps involve checking error codes, examining parameters, and performing basic checks.

2. Troubleshooting Information

a. Troubleshooting Strategy: This section describes the step-by-step actions to be taken during troubleshooting.

b. Auxiliary Equipment for Troubleshooting: Briefly explains the auxiliary equipment that can aid in troubleshooting.

c. Functional Inspection and Testing Using Testing Equipment VCADS Pro: Describes the process of conducting functional inspections and tests using the VCADS Pro testing equipment.

d. Error Code Information: Provides error code design information, a comprehensive list of all error codes, and specific information for each error code.

e. Components, Troubleshooting, and Specifications: Contains troubleshooting methods, numerical measurements of components, wiring diagrams, and relevant specifications.

f. Parameters: Highlights the significance of correctly set parameters to avoid malfunctions. This section includes a parameter list that outlines all limits and target values.

g. Control Device Function Description: Explains the function, input and output of the control device, and the communication between each control device.

h. Control Device, Active and Passive Measurements: Presents the measured values of the active and passive measurements of ACAS.

i. Software Functions: Describes the prerequisites for the software in ACAS to perform control and monitoring functions.

Basic Inspection of the Engine

Certain tests and inspections should be conducted with the safety lock lever unlocked. However, it is crucial to ensure that the machine cannot be accidentally operated with the safety lock lever unlocked. The purpose of the basic inspection is to provide quick and accurate information about the general condition of the engine. The following test items should be performed after reading the fault code and checking the parameters:

1. Cylinder Compression Test: This test aims to determine if there is any deviation in the compression pressure of a specific cylinder. While this test replaces the old stress check method, it does not provide precise numbers.

2. Cylinder Trim Test: This test helps identify if the fuel injection of the cylinder is deviated.

3. Supply Pressure Test: This test checks whether the supply pressure meets the specified requirements.

4. Sensor Test: This test ensures the functionality of all sensors.

VOLVO 88890300 Vocom Interface for VOLVO/Renault/UD/Mack Truck Diagnose

By conducting these basic inspections, you can gain valuable insights into the engine’s condition and identify any potential issues that may require further attention.

In conclusion, understanding Volvo excavator engine body instructions, performing basic inspections, and following troubleshooting instructions are essential for maintaining the optimal performance of your Volvo excavator. By adhering to these guidelines, you can ensure that your excavator’s engine operates smoothly, efficiently, and without any major issues.

More information about Volvo, please visit Volvo Trouble Repair.